Premium Faucet Parts Manufacturer in China

Tailor-Made, Embrace Diversity, Experience Precision

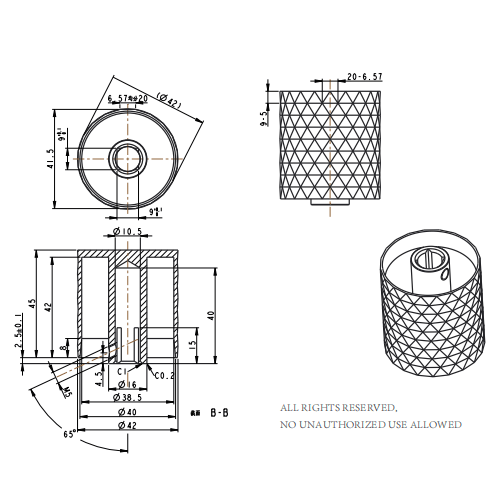

Our product

what can we make

HIPART is a leading manufacturer of high-quality metal components such as faucet parts, other metal parts and accessories

Faucet Body(By Gravity Casting)

- Our advantage

Why Choose Hiparts?

Throughout the design and manufacturing processes, we strictly adhere to the ISO 9001 quality management system, ensuring precision at every step.

HIGH QUALITY RAW MATERIALS

Throughout the design and manufacturing processes, we strictly adhere to the ISO 9001 quality management system, ensuring precision at every step.

Processing precision

Throughout the design and manufacturing processes, we strictly adhere to the ISO 9001 quality management system, ensuring precision at every step.

Customized services

Throughout the design and manufacturing processes, we strictly adhere to the ISO 9001 quality management system, ensuring precision at every step.

QUALITY ASSURANCE

Throughout the design and manufacturing processes, we strictly adhere to the ISO 9001 quality management system, ensuring precision at every step.

Delivery guaranteed

Throughout the design and manufacturing processes, we strictly adhere to the ISO 9001 quality management system, ensuring precision at every step.

- About Us

About HIPARTS

HIPART is a leading manufacturer of high-quality in metal components as faucet parts, other metal parts and accessories, headquartered in Kaiping, Guangdong Province, China, with a rich history spanning over 14 years

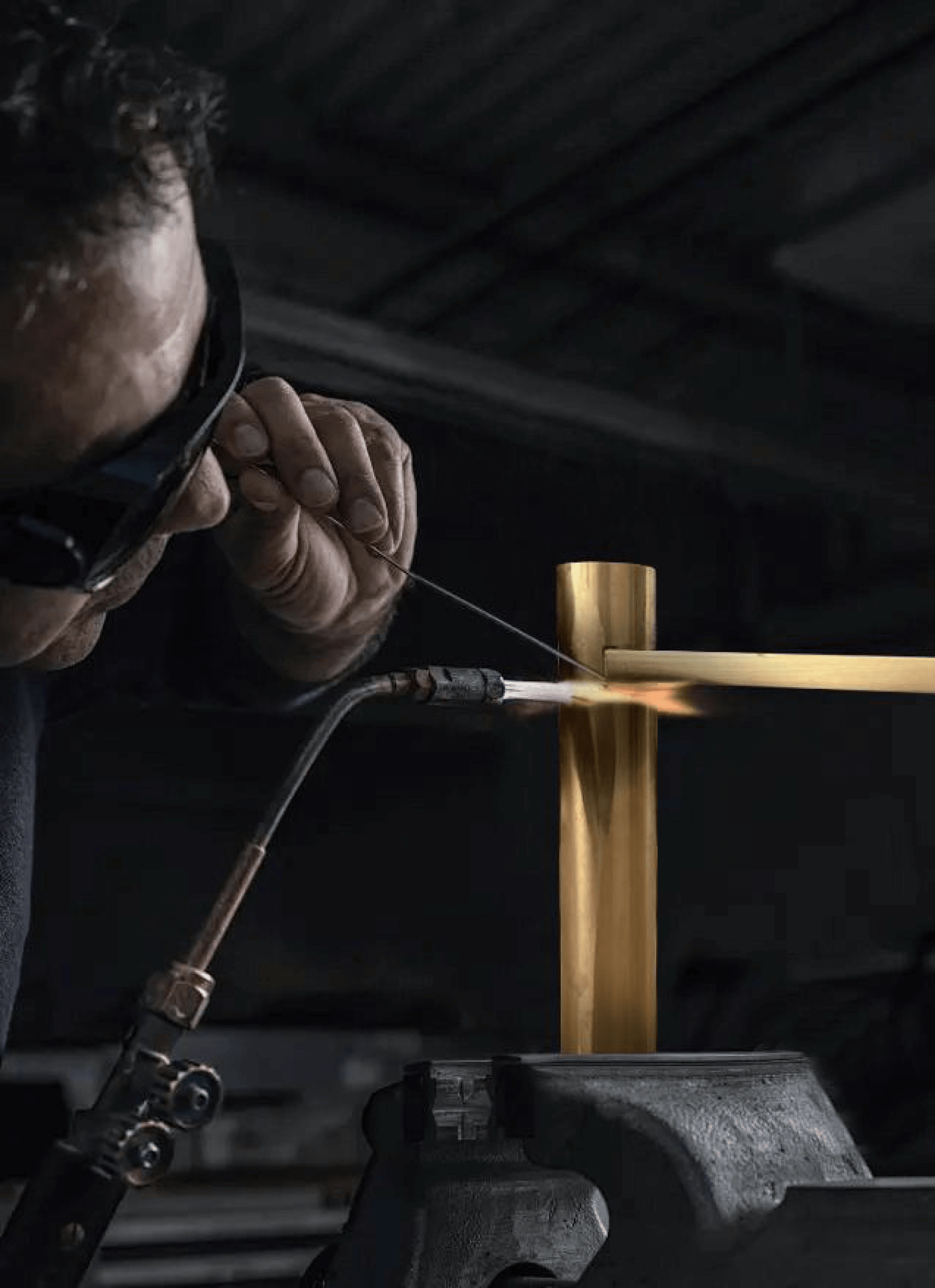

Faucet Parts manufacturing process video

I will share the detailed process of how Hipart manufactures faucet parts, reflecting our commitment to quality and innovation. Let’s enter the world of faucet parts manufacturing together!

Solid Core Making

This is where we shape the internal structure of the faucet. We use a special sand mixture to create a core that matches the internal design of the faucet.This core plays a vital role in ensuring the strength and integrity of the faucet.

Gravity Casting

Gravity casting is where the magic happens. We pour molten brass into the molds, where gravity ensures the brass fills every part of the mold evenly.This process is crucial for achieving the perfect shape and density.

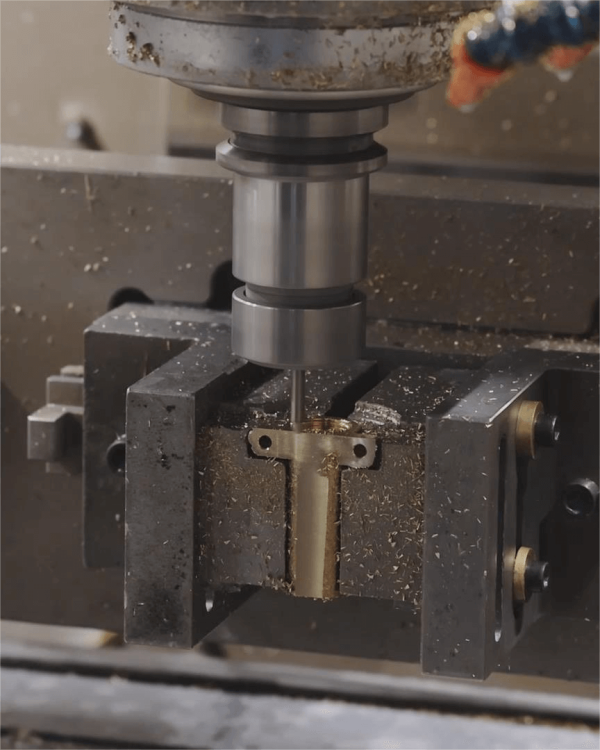

CNC

Faucet bodies go through CNC machining, Mainly peeling and processing threads. This is where we refine the details.Our state-of-the-art CNC machines ensure every curve and edge is flawless.

Polishing

The polishing of faucets is a crucial step in the manufacturing process that significantly enhances both the aesthetic appeal and the longevity of the product. This process involves smoothing and refining the surface of the faucet

Electroplating and PVD

Electroplating and PVD are essential in the faucet manufacturing process. While electroplating offers a classic, shiny finish with good protection, PVD provides a more durable, diverse, and eco-friendly option for modern faucets.

Ensure Quality and Tests

Quality testing is non-negotiable. We conduct numerous tests, from water pressure to leak tests, ensuring every faucet meets our stringent standards. This step is crucial for maintaining the trust of our customers and upholding our reputation for excellence.

- Customize your high-quality faucet accessories

Our Business Partner

- Customize your high-quality faucet accessories